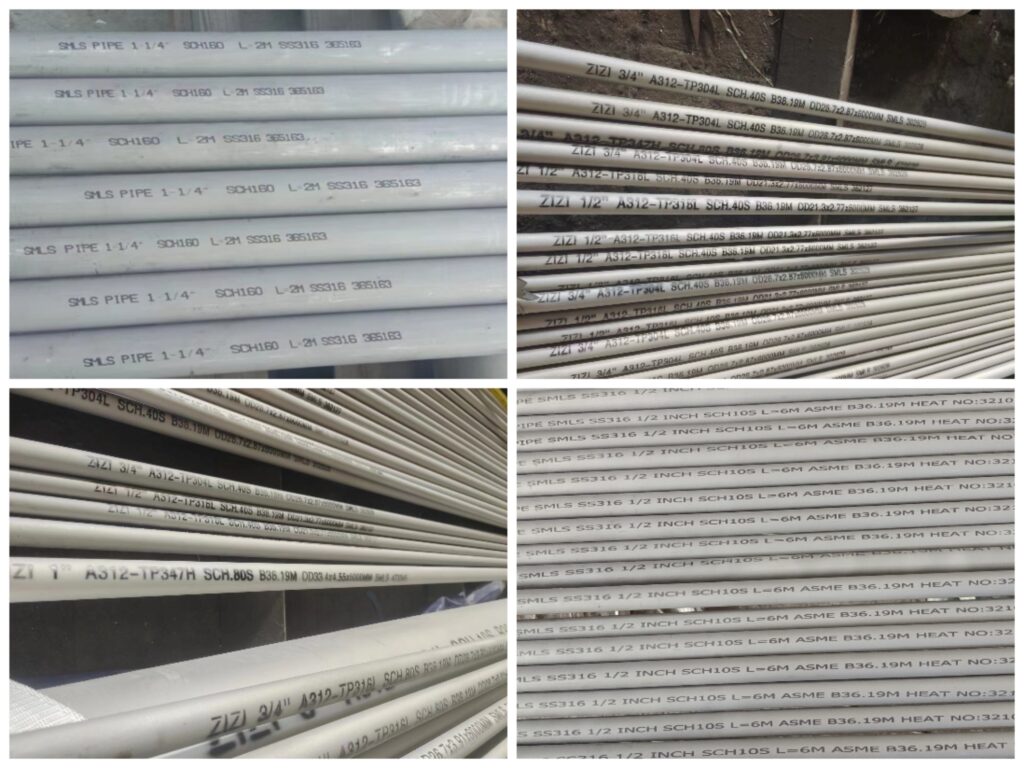

ASTM A312 Stainless steel pipe is a hollow long cylindrical steel, usually used as a pipeline for conveying fluids, and is widely used in industrial fields such as petroleum, chemical, medical, food, light industry, mechanical instruments, etc.

ASTM A312 Standard

This specification covers seamless, straight-seam welded, and heavily cold worked welded austenitic stainless steel pipe intended for high-temperature and general corrosive service.

Grades TP304H, TP309H, TP309HCb, TP310H, TP310HCb, TP316H, TP321H, TP347H, and TP348H are modifications of Grades TP304, TP309Cb, TP309S, TP310Cb, TP310S, TP316, TP321, TP347, and TP348, and are intended for high-temperature service.

Table X1.1 lists the standardized dimensions of welded and seamless stainless steel pipe as shown in ANSI B36.19. These dimensions are also applicable to heavily cold worked pipe. Pipe having other dimensions may be furnished provided such pipe complies with all other requirements of this specification.

Specification of Stainless Steel Pipe

| Processing Method | Seamless and Welded |

| Size Range | 1/8” – 30” / DN6 – 750 |

| Thickness Schedule | SCH 10S- SCH 160, XXS |

| Length | 6m or 12 m or Random |

| Standard | ASME B36.19M,ASME B36.10M |

| Surface Treatment | Polish , Mirror , Epoxy Powder FBE, 2PE, 3PE Coating |

| Material Grade | ASTM A312 TP304/304L/304H, 316/316L, 310S, 317, 347, 904L, S32205, S31803, 32750, 32760, S32550 |

ASTM A312 Material Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo |

| ASTM A312 TP304 | MIN | 8.00 | 18.00 | ||||||

| MAX | 0.08 | 2.00 | 0.05 | 0.03 | 1.00 | 11.00 | 20.00 | ||

| ASTM A312 TP304L | MIN | 8.00 | 18.00 | ||||||

| MAX | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 13.00 | 20.00 | ||

| ASTM A312 TP316 | MIN | 11.00 | 16.00 | 2.00 | |||||

| MAX | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 14.00 | 18.00 | 3.00 | |

| ASTM A312 TP316L | MIN | 10.00 | 16.00 | 2.00 | |||||

| MAX | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 14.00 | 18.00 | 3.00 |

ASTM A312 Material Mechanical Property

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| ASTM A312 TP304 | 515min | 205 min | 35 min |

| ASTM A312 TP304L | 485 min | 170 min | 35 min |

| ASTM A312 TP316 | 515min | 205min | 35 min |

| ASTM A312 TP316L | 485 min | 170 min | 35 min |

Stainless Steel Pipe Dimension

ASTM A312 TP304 stainless steel pipe is a general purpose stainless steel pipe used in different industries. Its diameter ranges from 1/8” to 30”, and thickness ranges from SCH 5S to SCH 80S.

| Stainless Steel Pipe (ASME B 36.19M) | ||||||||||

| Nominal Size | OD | Sch5s | Sch10s | Sch40s | Sch80s | |||||

| DN | NPS | 0 | T | kg/m | T | kg/m | T | kg/m | T | kg/m |

| 6 | 1/8 | 10.3 | 1.24 | 0.28 | 1.73 | 0.37 | 2.41 | 0.47 | ||

| 8 | 1/4 | 13.7 | 1.65 | 0.49 | 2.24 | 0.63 | 3.02 | 0.8 | ||

| 10 | 3/8 | 17.1 | 1.65 | 0.63 | 2.31 | 0.84 | 3.2 | 1.1 | ||

| 15 | 1/2 | 21.3 | 1.65 | 0.82 | 2.11 | 1 | 2.77 | 1.27 | 3.73 | 1.62 |

| 20 | 3/4 | 26.7 | 1.65 | 1.04 | 2.11 | 1.28 | 2.87 | 1.69 | 3.91 | 2.2 |

| 25 | 1 | 33.4 | 1.65 | 1.33 | 2.77 | 2.09 | 3.38 | 2.5 | 4.55 | 3.24 |

| 32 | 1 1/4 | 42.2 | 1.65 | 1.68 | 2.77 | 2.7 | 3.56 | 3.39 | 4.85 | 4.47 |

| 40 | 1 1/2 | 48.3 | 1.65 | 1.95 | 2.77 | 3.11 | 3.68 | 4.05 | 5.08 | 5.41 |

| 50 | 2 | 60.3 | 1.65 | 2.44 | 2.77 | 3.93 | 3.91 | 5.44 | 5.54 | 7.48 |

| 65 | 2 1/2 | 73.0 | 2.11 | 3.77 | 3.05 | 5.26 | 5.16 | 8.63 | 7.01 | 11.41 |

| 80 | 3 | 88.9 | 2.11 | 4.6 | 3.05 | 6.45 | 5.49 | 11.29 | 7.62 | 15.27 |

| 90 | 31/2 | 101.6 | 2.11 | 5.29 | 3.05 | 7.4 | 5.74 | 13.57 | 8.08 | 18.63 |

| 100 | 4 | 114.3 | 2.11 | 5.96 | 3.05 | 8.36 | 6.02 | 16.07 | 8.56 | 22.32 |

| 125 | 5 | 141.3 | 2.77 | 9.67 | 3.4 | 11.57 | 6.55 | 21.77 | 9.53 | 30.97 |

| 150 | 6 | 168.3 | 2.77 | 11.55 | 3.4 | 13.48 | 7.11 | 28.26 | 10.97 | 42.56 |

| 200 | 8 | 219.1 | 2.77 | 15.09 | 3.76 | 19.96 | 8.18 | 42.55 | 12.7 | 64.64 |

| 250 | 10 | 273.1 | 3.4 | 23.08 | 4.19 | 27.78 | 9.27 | 60.31 | 12.7 | 96.01 |

| 300 | 12 | 323.9 | 3.96 | 31.89 | 4.57 | 36 | 9.53 | 73.88 | 12.7 | 132.08 |

| 350 | 14 | 355.6 | 3.96 | 35.06 | 4.78 | 41.3 | ||||

| 400 | 16 | 406.4 | 4.19 | 42.41 | 4.78 | 47.29 | ||||

| 450 | 18 | 457.2 | 4.19 | 47.77 | 4.78 | 53.26 | ||||

| 500 | 20 | 508 | 4.78 | 60.46 | 5.54 | 68.61 | ||||

| 550 | 22 | 558.8 | 4.78 | 66.57 | 5.54 | 75.53 | ||||

| 600 | 24 | 609.6 | 5.54 | 84.16 | 6.35 | 94.45 | ||||

| 750 | 30 | 762 | 6.35 | 120.72 | 7.92 | 147.36 | ||||

Stainless steel Pipe Permitted Tolerance in Wall Thickness

| Tolerance,%from Nominal | ||

| NPS Designator | Over(+) | Under (-) |

| 1/8 to 21/2 incl.,all t/D ratios | 20.0 | 12.5 |

| 3 to 18 incl.,t/D up to 5% incl. | 22.5 | 12.5 |

| 3 to 18 incl.,t/D>5% | 15.0 | 12.5 |

| 20 and larger,weldedall t/D ratios | 17.5 | 12.5 |

| 20 and larger,seamlesst/D up to 5% incl. | 22.5 | 12.5 |

| 20 and larger,seamlesst/D>5% | 15.0 | 12.5 |

| t = Nominal Wall ThicknessD = Ordered Outside Diameter | ||

A312 Pipe Manufacturing Types

ASTM A312 Stainless steel pipe covers following manufacturing types (Including hot finished or cold finished):

a. Seamless Pipe (SMLS): It covers stainless steel seamless pipe that manufactured in any process that can not be involved in the welding process.

b. Welded Pipe (WLD): It covers welded pipe that manufactured by an automatic welding process that does not add filler metal during welding.

c. Cold Worked Pipe (HCW pipe): Heavily cold-worked (HCW) pipe shall be made by applying cold working of not less than 35 % reduction in thickness of both wall and weld to a welded pipe prior to the final anneal. No filler shall be used in making the weld.

d. Welded pipe and HCW pipe of NPS 14 and smaller shall have a single longitudinal weld.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....